Flynn Drilling has got you covered when it comes to the installation of a heat exchange ground source looping systems for your future projects. Our knowledge and technical expertise has played a key role in the geothermal industry for over 30 years. We utilize modern equipment and highly qualified personnel to achieve superior results on all geothermal projects. Flynn Drilling is an Accredit Installer of the International Ground Source Heat Pump Association (IGSHPA) and North American Technician Excellence (NATE) certified. Check with your local HVAC installer or Electric COOP for any rebates you may receive for the installation of a heat exchange ground source system.

What is Geothermal?

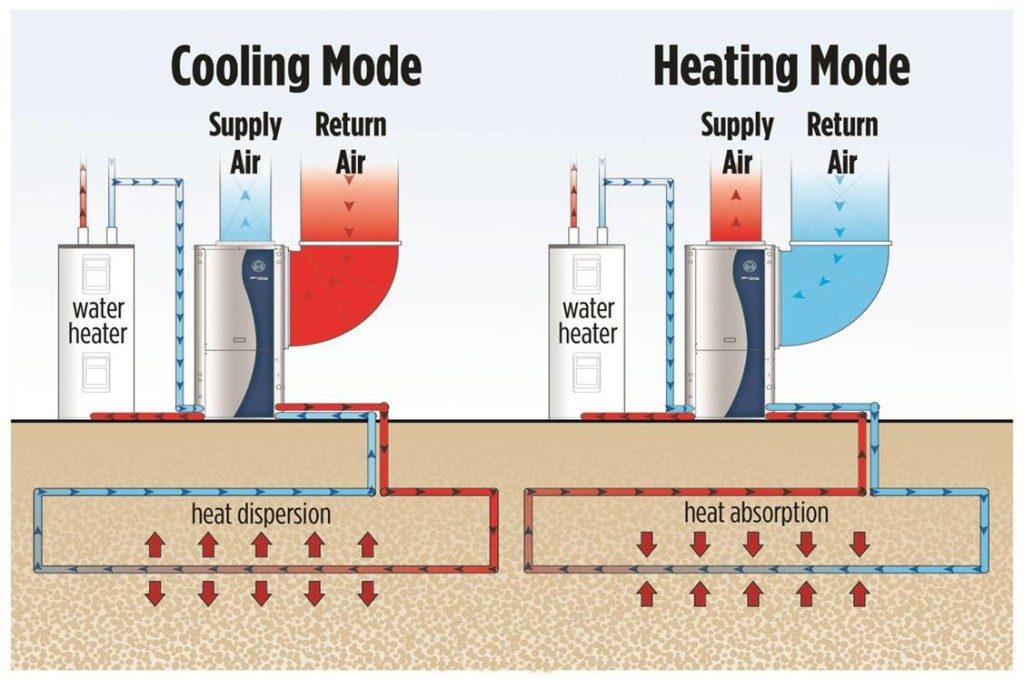

Geothermal is a renewable energy source that utilizes the earths continuously produced heat. The geothermal units use the earth’s natural heat to warm and cool your home by pumping circulated water through a geothermal looping field for a cost effective, sustainable, and environmentally friendly comfort throughout your home. The ground stays at a relatively constant temperature throughout the seasons, providing a warm heat source in the winter and a cool heat sink in the summer that keeps your home with consistent comfort.

Winter

During the winter the unit absorbs the heat stored in the ground by sending water out through the geothermal looping field then circulating back to the furnace where it’s concentrated and then sent as warm, comfortable air throughout the home.

Summer

During the summer the units absorb heat from your home and transfers it to the looping field where it is sent out and absorbed by the cooler earth temperatures, the cool water returning from the looping field is then concentrated to create cool air throughout the home.

What kind of looping field is best for you?

There are 4 common types of geothermal looping fields that can be installed, vertical, horizontal, open loop system, and pond loop. The elements to consider for your application would be; type of soil, space availability, accessibility, the amount of heat exchange needed (measured by tons), etc. The horizontal method takes up a substantial amount more space, but is a lot more feasible for locations where vertical drilling can be very poor and may require us to use additional methods to keep the drilled hole open. Although in tight areas, like in smaller lot subdivisions, the vertical method takes up less room which allows us to apply more tons of heat exchange.

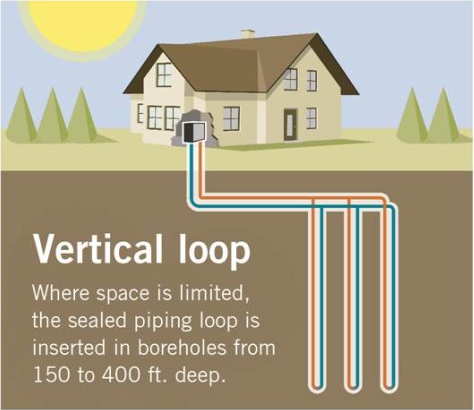

Vertical Looping Field

On a standard residential vertical installation each Ton of heat exchange is a 150ft 6 inch drilled hole, and a 510ft x ¾” U bend HDPE Polyurethane plastic pipe is installed and grouted to MO DNR standards, each ton needs to be spaced out 10 to 12ft, once all the holes are drilled they will be piped into a reverse return 1 ¼ header pipe that is piped to the geothermal unit. The diagram below is based on a 3-ton system.

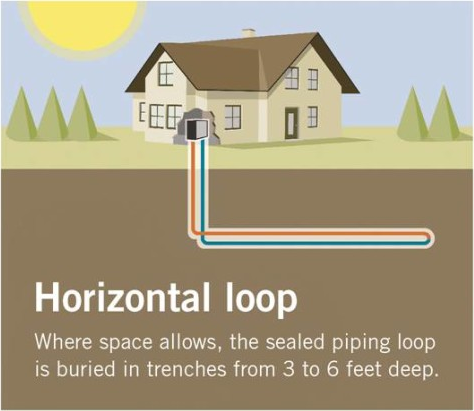

Horizontal Looping Field

On a standard residential horizontal looping field each Ton of heat exchange is a 250ft run of ¾ HDPE Polyurethane pipe that is either trenched in or bored in at a depth of 5 to 10ft, 12 to 15ft apart, these will be piped into a reverse return 1 ¼ header pipe that is piped to the geothermal unit. The diagram below is based on a 3-ton system.

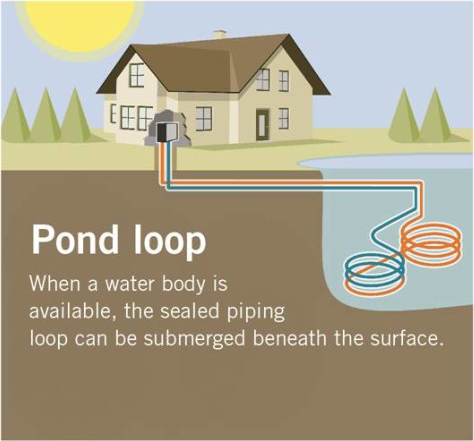

Pond Looping Field

A less common yet most cost-efficient option would be the pond looping field. This is only an option if the site has an adequate body of water. A supply line pipe is run underground from the building to the water and coiled into circles at least eight feet under the surface to prevent the lines from freezing. These coils should only be placed in a water source that meets minimum volume, depth, and quality criteria all determined on a case by case basis.

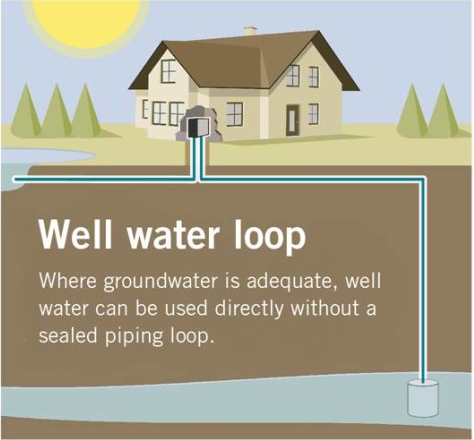

Well Water or Open Loop System

An open loop system is directly connected to a ground water source such as a pond or a well and directly pumps the water into the home or building to the heat pump unit where it is used for heating and cooling. This has become a less common practice, because of the improvements in the closed loop technologies over the years.